淬火油復合劑 Ciba OQ0450

Ciba® Irgasol® OQ 4050

OQ 4050 is a high performance package to formulate quenching oils.

Description:

Irgasol® OQ 4050 is a synergistic blend of Antioxidants,quenching speed improvers and otherperformance enhancing additives.

Recommended treat level:

Irgasol® OQ 4050 can be used at the treat level from 2% - 6% in mineral oil to formulate quenching oils for cold quenching, mar-quenching and bright quenching

applications.

Performance Benefits:

• Excellent thermo- oxidative stability which ensures higher quenching oil life.

• Excellent sludge/ deposit control ensures clean components after quenching.

• Minimize vapor phase and enhance boiling phase to achieve optimum hardness.

• Controlled cooling in convection phase

• Provides corrosion protection to ferrous as well as non-ferrous metals. Protects copper metal present in certain quenching systems.

• Compatible with wide range of base stocks.

Application:

Quenching oil formulated by using Irgasol® OQ 4050 can be used for cold quenching, bright quenching and mar-quenching applications. Irgasol® OQ 4050 at a

treat level of 1-2% can also be used to formulate heat transfer fluids.

Physical Properties:

|

Appearance

|

Dark viscous liquid

|

|

Specific Gravity at 20°C

|

0.908

|

|

Solubility is mineral oil

|

Soluble

|

Typical performance data

|

Base Stock

|

GP I SN 70

|

|

Treat level of Irgasol® OQ 4050

|

4%

|

|

Bath temperature

|

60ºC

|

Thermo-oxidative properties

|

Test parameters

|

Results

|

|

Rotating Pressure Vessel Oxidation test (ASTM D 2272)

|

188 minutes

|

|

High Pressure Differential Scanning calorimeter

(ASTM D 6186)

|

80 minutes

|

|

Dry TOST ( JIS K 2242 )

Temperature: 165ºC

Air : 10 lit/hr

Catalyst : Copper and Iron

|

Viscosity increase : 15%

TAN change : 2.4

Sludge% ( wt./Volume : 0.42

|

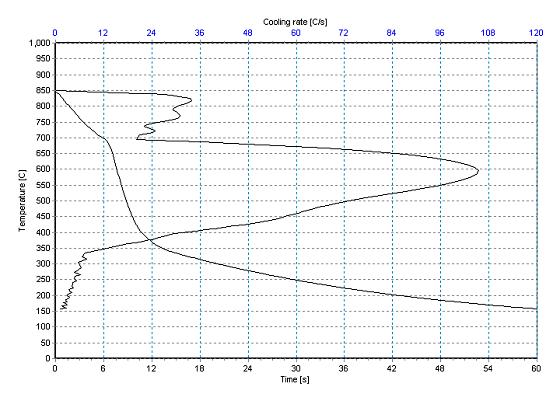

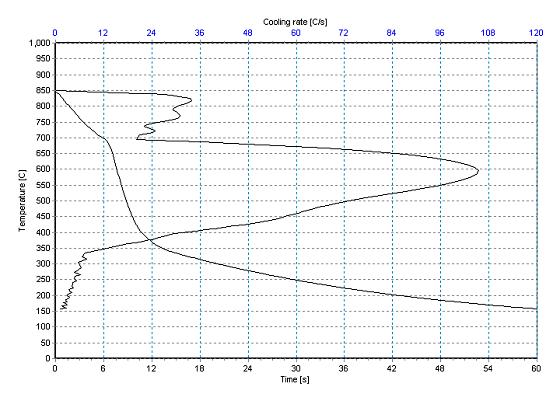

Cooling Curve

?

CIBA 公司推出的針對淬火油的復合添加劑。

是一種抗氧化劑�����,淬速改良劑以及其它增強性能的添加劑協(xié)同作用的復合添加劑�����。

具有:優(yōu)異的熱氧化穩(wěn)定性��,確保較高的淬火油壽命��;

優(yōu)秀的污泥和沉淀物控制����,確保淬火后組件清潔;

氣相最小化�����,提高沸騰階段��,以達到最佳硬度����;

控制冷卻對流階段;

提高黑金屬和有色金屬的防腐蝕保護���;

基礎油廣泛的兼容性����;

產(chǎn)品詳細資料請與027-83305579聯(lián)系�。

?

?